FRP Valve Enclosure Protects Motorized Butterfly ValveCase Study

Reliable Protection for Water Infrastructure

Reliable Protection for Water Infrastructure

New Kent County’s water system serves several growing subdivisions, requiring dependable operation of its elevated storage tank to maintain consistent water pressure and supply. To improve system reliability at the Bottoms Bridge Elevated Water Tank, the County partnered with the engineering team at Dewberry, a firm specializing in water system expansion and rehabilitation, to design improvements for the site.

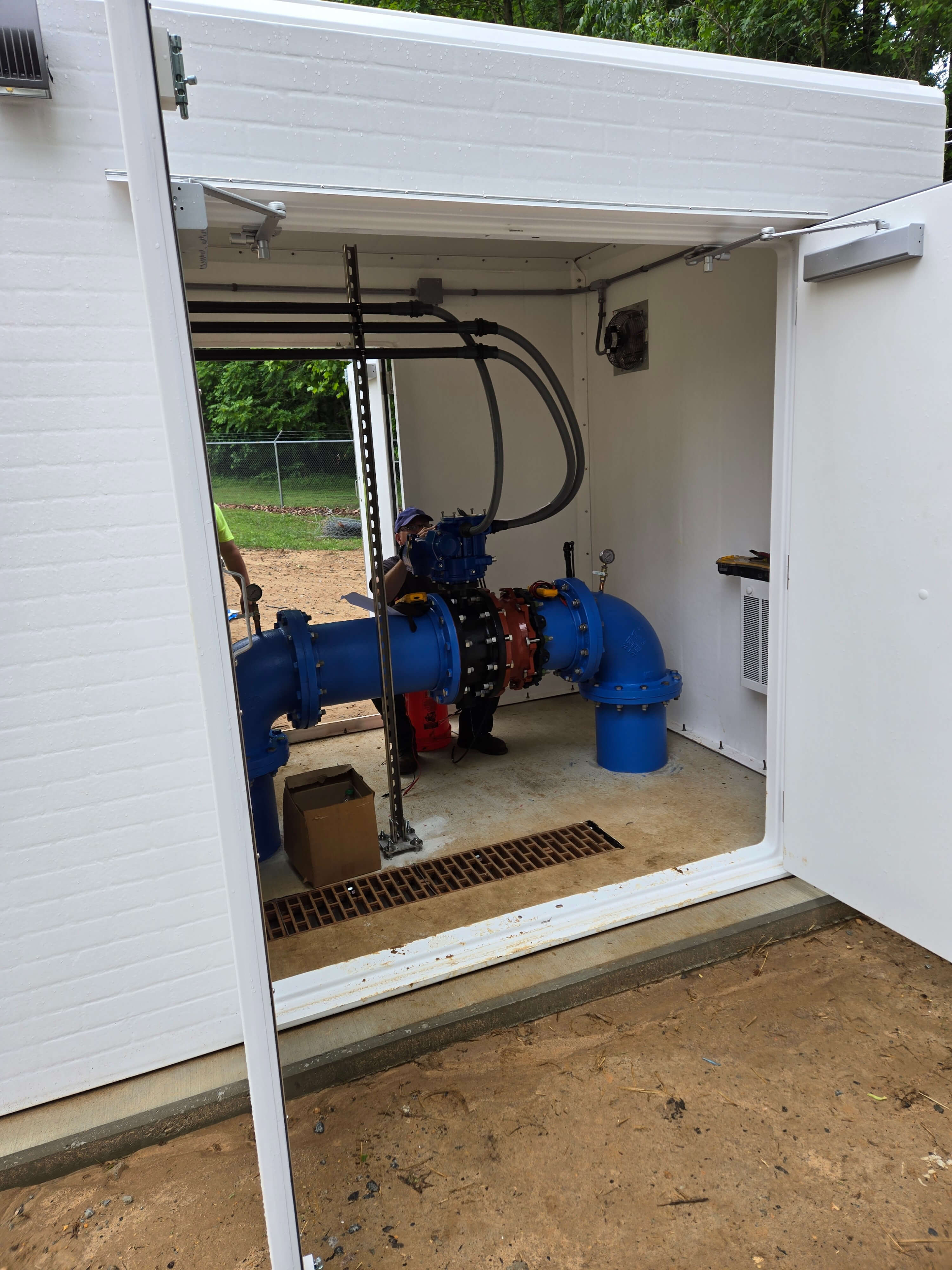

The project included the installation of a new control valve, approximately 200 linear feet of 12-inch waterline, and a motorized butterfly valve housed within a fiberglass (FRP) shelter. The motorized valve automatically opens and closes based on the tank’s water level to control filling and maintain proper system balance. The FRP shelter provides long-term protection against humidity, corrosion, and freezing temperatures.

Shelter Works collaborated with Christian Workman, Sales Engineer of Tencarva Machinery Company and the engineers at Dewberry’s Richmond, VA office to design and manufacture a custom 8' x 12' x 8' fiberglass valve enclosure that ensures reliable operation and minimal maintenance for years to come.

Why a Motorized Butterfly Valve Needs Protection

The motorized butterfly valve plays a critical role in regulating water flow to the elevated tank. It opens or closes automatically in response to level sensors in the storage tank, maintaining the system’s capacity and pressure without manual intervention.

Because this valve operates outdoors and connects directly to a live waterline, it is exposed to moisture, condensation, and freezing conditions, all of which can compromise performance or damage sensitive control components. Housing the valve in a fiberglass shelter prevents corrosion, ensures reliability, and simplifies year-round maintenance.

Custom Shelter Design for Humid and Cold Conditions

Shelter Works designed and manufactured an FRP shelter to meet the site's requirements and climate conditions. The building's fiberglass construction provides corrosion resistance far superior to metal or wood structures, making it ideal for humid environments commonly found near water storage facilities.

Key design features include:

- Two Sets of Double Doors:

Double doors on both sides allow full access to the valve, simplifying inspection and maintenance. - Exterior Mounted Electric Panel:

The electrical panel is mounted outside the shelter to minimize exposure to internal humidity and reduce damage to electrical connections that can result from condensation build-up. - Wall Heater for Freeze Protection:

While the shelter’s standard 1-1/2” wall foam provides ample freeze protection, an electric heater was added for additional frost protection during sustained periods of temperatures below freezing. - Dusk-to-Dawn Lighting:

Outdoor lights above each entrance enhance safety and visibility for nighttime or early-morning maintenance. - Ventilation System:

An exhaust fan with a matching intake maintains air circulation and reduces humidity inside the shelter, extending the lifespan of the valve.

Benefits of Shelter Works FRP Shelter

Shelter Works manufactures fiberglass enclosures engineered to perform for decades in demanding field environments. For the New Kent County project, FRP construction offers several key advantages:

- Corrosion Resistance:

The composite materials used in Shelter Works enclosures do not rust, rot, or degrade in humid or chemical-rich environments, ensuring long-term reliability around water infrastructure. - Thermal Insulation:

Foam core insulation in the roof and walls provides thermal stability, reducing freeze risk, and minimizing condensation throughout the year. - Lightweight, Structural Strength:

The shelter arrives on-site in one piece. Shelter Works' lightweight design enables easy installation and provides a rigid structure that resists impact, UV degradation, and weathering. - Low Maintenance:

Unlike metal buildings, FRP shelters require virtually no maintenance, no repainting, rust prevention, or corrosion control, reducing lifecycle costs.

Why Shelter Works

Every Shelter Works fiberglass enclosure is engineered to maintain structural integrity and an optimal internal operating environment throughout its service life. For New Kent County, this means consistent valve performance, reliable operation during extreme temperatures, and safe, dry working conditions for maintenance personnel.

When asked about his experience working with Shelter Works on this project, Workman stated “Shelter Works was a great partner throughout this project. Their team communicated clearly, provided timely updates, and ensured the enclosure was built to meet the project’s exact specifications. The entire process was efficient and straightforward, which helped us deliver a reliable solution to our customer”

This project demonstrates how collaboration between Dewberry, Tencarva, and Shelter Works resulted in an intelligently designed fiberglass enclosure that protects critical water system assets and provides durability, safety, and peace of mind for operators responsible for uninterrupted service to the community.

By selecting a Shelter Works FRP shelter for their valve enclosure, New Kent County ensured the butterfly valve's reliable operation despite exposure to moisture and freezing temperatures. The custom design, corrosion-resistant materials, and thoughtful electrical and thermal features illustrate how Shelter Works provides engineered protection solutions that support the long-term performance of vital water infrastructure.